All Services

Solving industry challenges with enthusiasm,

professionalism and diligence.

Our Objective

TO MAKE YOUR PROJECT AS TURNKEY AS POSSIBLE

That’s why we provide the parts and supplies you need along with the advice, knowledge and solutions to meet any of your industry challenges. Whatever your drilling challenges are, our experienced team will work to find a solution for you.

.png)

Most Common Services

Threading

Continued investment in our people and equipment ensures superior threading services, as well as short turn-around time. With many large bore CNC lathes and hundreds of gauges, we are prepared to meet all your threading needs. For casing or drill rod, virtually any thread, pipe size or length -- our priority is to supply threading services that meet your needs and expectations.

REQUEST A QUOTE >

Design & Drafting

Using the latest CAD (computer aided design) software, Western Drilling’s team of engineers can design, draft and stamp your project. Often beginning with sketches and concepts, we will work with you to complete your design from beginning to completion.

REQUEST A QUOTE >

Most common services

Welding

At our machine shop, we have a large welding area and offer a variety of welding services. We weld by MIG, TIG, and stick -- always preheating and post-heating to ensure a proper weld. We have experience welding many different materials including, alloy steel, stainless and non mag, and aluminum. Either by your supplied welding specification or our own internal procedures, our Journeymen and B-pressure welders will make sure your parts are fabricated to code.

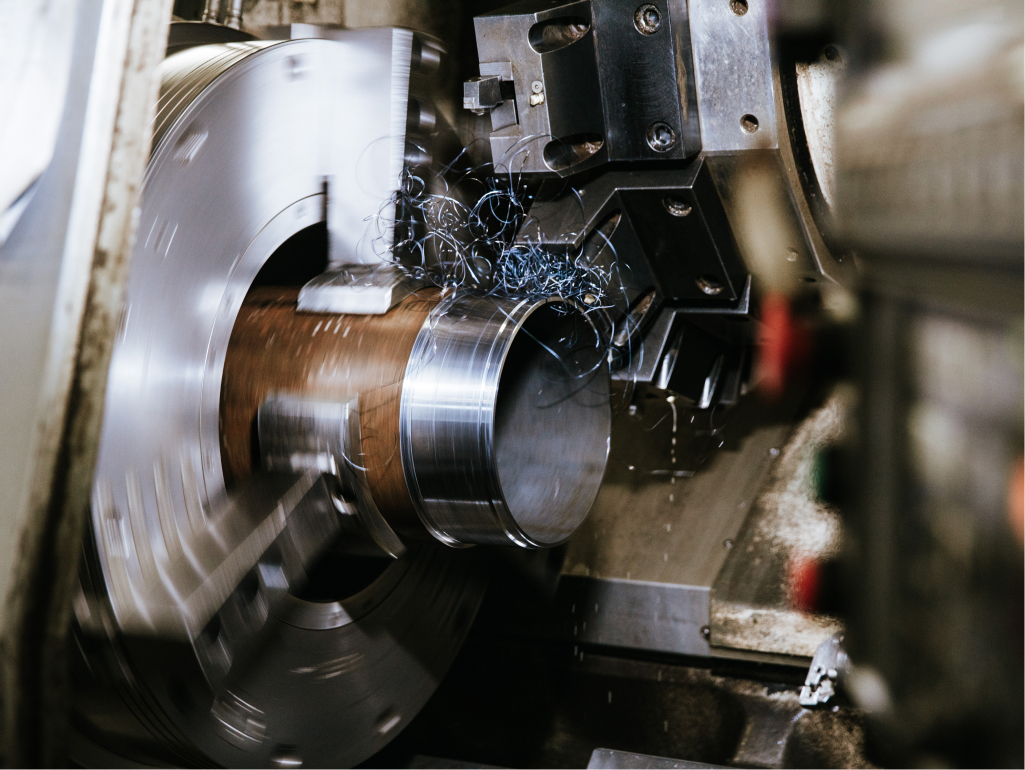

REQUEST A QUOTE >Custom Machining & Prototyping

Our machine shop is fully loaded with CNC lathes, CNC mills, surface grinders, drill presses, and manual machines. Our material list is long and comprehensive, including everything from carbon steel and stainless steels and iconels, to red metals and plastics. When you need a prototype built, custom machining work done, or just a reliable, dependable and accurate machine shop, we’ve got your back.

Production Machining

Our precision CNC’s can carry a high capacity of parts and complete batches of any amount with precision and repeatability. Whether it is part 1 or part 5,000 the variation in dimensional accuracy will never exceed the acceptable tolerances. A large production run can save your company a considerable amount of money.

REQUEST A QUOTE >Threading

Continued investment in our people and equipment ensures superior threading services, as well as short turn-around time. With many large bore CNC lathes and hundreds of gauges, we are prepared to meet all your threading needs. For casing or drill rod, virtually any thread, pipe size or length -- our priority is to supply threading services that meet your needs and expectations.

REQUEST A QUOTE >design & prototyping

Using the latest CAD (computer aided design) software, Western Drilling’s team of engineers can design, draft and stamp your project. Often beginning with sketches and concepts, we will work with you to complete your design from beginning to completion.

REQUEST A QUOTE >All Services

assembly & pressure

testing

At Western Drilling Tools, we have breakout tables, overhead cranes, hydraulic power packs, assembly benches, and pressuring testing up to 20,000 PSI. We provide graphed results and charting for the pressure testing service we provide, so that you always have testing history on hand.

Get a Quote >coatings, hardening,

& heat treatments

To be as turnkey as possible to accommodate your needs, we can offer a wide range of coatings and heat treatment services including carburizing, stress relieving, hardfacing, laser cladding, liquid and gas nitriding, boronizing and shot peening. We also offer phosphating, electroless nickel coating (ENC), and painting.

Get a Quote >Custom machining & prototyping

Our machine shop is fully loaded with CNC lathes, CNC mills, surface grinders, drill presses, and manual machines. Our material list is long and comprehensive, including everything from carbon steel and stainless steels and iconels, to red metals and plastics. When you need a prototype built, custom machining work done, or just a reliable, dependable and accurate machine shop, we’ve got your back.

Get a Quote >design & drafting

Using the latest CAD (computer aided design) software, Western Drilling’s team of engineers can design, draft and stamp your project. Often beginning with sketches and concepts, we will work with you to complete your design from beginning to completion.

Get a Quote >non destructive testing & destructive testing

We offer a wide variety of NDT methods as well as destructive testing options when required. Some of the testing methods we provide include x-ray testing, magnetic particle inspection (MPI), liquid penetrant inspection (LPI), thread inspection, mechanical testing, chemical testing, pull test to destruction, impact testing, and hardness testing.

Get a Quote >Production machining

Our precision CNC’s can carry a high capacity of parts and complete batches of any amount with precision and repeatability. Whether it is part 1 or part 5,000 the variation in dimensional accuracy will never exceed the acceptable tolerances. A large production run can save your company a considerable amount of money.

Get a Quote >pull testing

Pull testing is regularly performed to certify lifting equipment. With our pull testing expertise and network, we can get items pull tested and certified up to 200,000 lbs. Many of our customers require pull tested and certified lifting tools, such as lifting subs, lifting collars, and lifting clamps. We have the flexibility and expertise to meet the unique specifications and requirements of your business.

Get a Quote >Threading

Continued investment in our people and equipment ensures superior threading services, as well as short turn-around time. With many large bore CNC lathes and hundreds of gauges, we are prepared to meet all your threading needs. For casing or drill rod, virtually any thread, pipe size or length - our priority is to supply threading services that meet your needs and expectations.

Get a Quote >want to see every product that we offer?

Contact Us

Looking for more information on pricing, machine capabilities, or products? Contact us today.

.png)

.svg)